Understanding the #21 Drill Size: A Comprehensive Guide

When it comes to drilling, precision is paramount. Choosing the right drill bit size for the job can be the difference between a successful project and a frustrating failure. One specific size that often comes up in various applications is the #21 drill size. This article provides a comprehensive overview of the #21 drill size, covering its dimensions, common uses, and essential considerations for selecting the appropriate bit.

What is the #21 Drill Size?

The #21 drill size is a numbered drill bit that falls within a specific range of fractional and metric sizes. Numbered drill bits are designated by numbers rather than fractions or millimeters. This system is particularly useful for fine-tuning hole sizes for tapping threads or achieving precise fits. The #21 drill size corresponds to a diameter of 0.1590 inches, which is equivalent to approximately 4.039 millimeters. Understanding this measurement is crucial for ensuring accurate drilling.

Common Applications of the #21 Drill Size

The #21 drill size is commonly used in a variety of applications, spanning from metalworking to woodworking and beyond. Here are some of the most frequent uses:

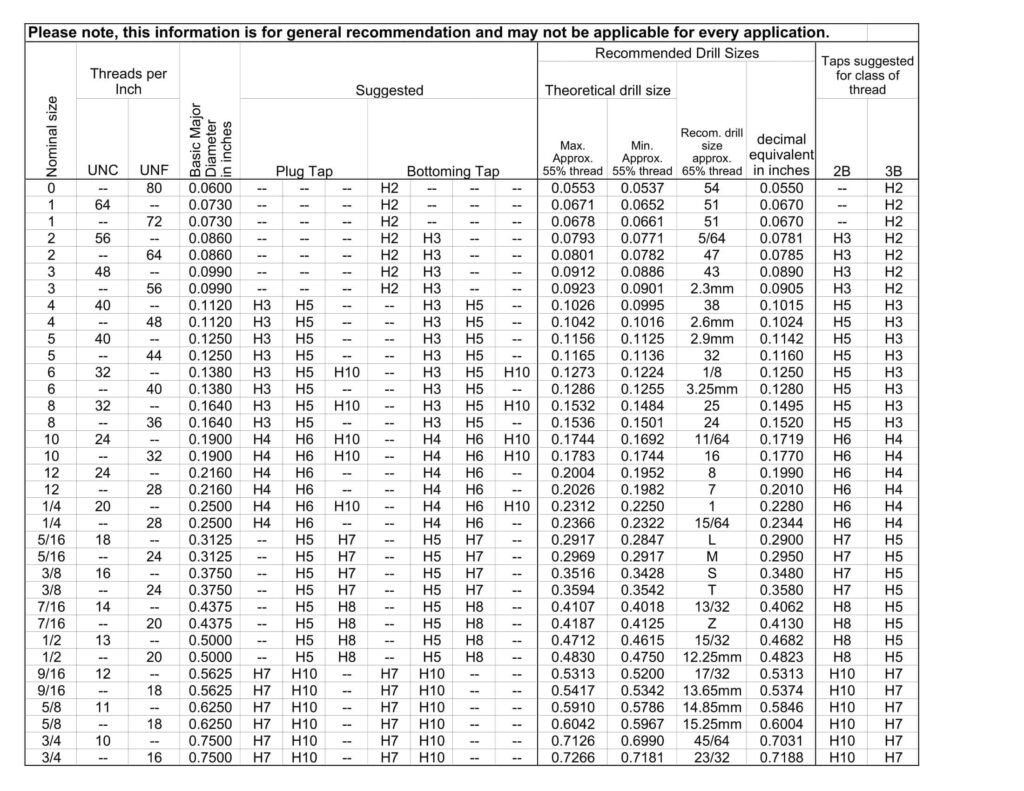

- Tapping Threads: One of the primary uses of the #21 drill size is for creating pilot holes for tapping threads. Specifically, it is often used as a tap drill for a 8-32 machine screw. Tapping involves cutting threads into a pre-drilled hole to allow screws or bolts to be securely fastened. The #21 drill size creates a hole that is appropriately sized to accommodate the tap without stripping the threads.

- Sheet Metal Work: In sheet metal fabrication, the #21 drill size is useful for creating precise holes for rivets, screws, or other fasteners. The accuracy of the hole size is critical to ensure a secure and clean connection.

- Electronics Assembly: The electronics industry frequently uses small drill bit sizes for creating holes in circuit boards or enclosures. The #21 drill size can be suitable for mounting small components or running wires through panels.

- Woodworking: While less common than larger drill bit sizes, the #21 drill size can be used in woodworking for creating pilot holes for small screws or for detailed decorative work. It is particularly useful when working with hardwoods that are prone to splitting.

- Model Making: Hobbyists and model makers often rely on numbered drill bits for creating accurate holes in their projects. The #21 drill size is useful for adding small details or attaching miniature components.

Materials Suitable for the #21 Drill Size

The #21 drill size can be used on a variety of materials, but it’s important to select the right type of drill bit for the specific material being drilled. Here are some common materials and considerations:

- Steel: High-speed steel (HSS) drill bits are generally suitable for drilling steel. For harder steels, cobalt drill bits may be necessary to withstand the heat and friction.

- Aluminum: HSS drill bits also work well for aluminum. Using a lubricant can help prevent the aluminum from sticking to the drill bit.

- Wood: Standard HSS drill bits or brad point drill bits can be used for wood. Brad point drill bits have a sharp point that helps to prevent the drill bit from wandering.

- Plastic: HSS drill bits can be used for drilling plastic, but it’s important to use a slow speed to prevent the plastic from melting.

- Brass: Brass can be drilled with HSS drill bits. Similar to aluminum, using a lubricant can help prevent the brass from sticking to the drill bit.

Choosing the Right Drill Bit Material

Selecting the right drill bit material is essential for achieving optimal performance and extending the life of the drill bit. Here are some common drill bit materials and their characteristics:

- High-Speed Steel (HSS): HSS drill bits are a versatile and cost-effective option suitable for a wide range of materials. They offer a good balance of hardness and toughness.

- Cobalt: Cobalt drill bits are made from HSS with a percentage of cobalt added to improve heat resistance and hardness. They are ideal for drilling harder materials like stainless steel and cast iron.

- Carbide: Carbide drill bits are extremely hard and heat-resistant, making them suitable for drilling very hard materials like hardened steel and titanium. They are more brittle than HSS or cobalt drill bits and are typically more expensive.

- Titanium Nitride (TiN) Coated: TiN coating reduces friction and increases the wear resistance of HSS drill bits. This coating helps to extend the life of the drill bit and improve drilling performance.

Essential Considerations for Using the #21 Drill Size

When working with the #21 drill size, several key considerations can help ensure accuracy and safety:

- Drill Speed: Using the correct drill speed is crucial for preventing overheating and extending the life of the drill bit. For harder materials like steel, a slower speed is generally recommended. For softer materials like aluminum and plastic, a higher speed can be used. Consult a drill speed chart for specific recommendations based on the material being drilled.

- Lubrication: Applying a lubricant can help to reduce friction and heat, making drilling easier and preventing the drill bit from binding. For metalworking, cutting oil is a common choice. For woodworking, a dry lubricant or wax can be used.

- Pilot Hole: When drilling larger holes, it’s often helpful to start with a smaller pilot hole. This helps to guide the larger drill bit and prevent it from wandering. However, for the #21 drill size, it is typically the pilot hole itself, especially for tapping.

- Drill Bit Sharpness: A sharp drill bit is essential for clean and accurate drilling. Dull drill bits can cause the material to tear or chip, and they require more force to operate, increasing the risk of breakage. Regularly inspect your drill bits and sharpen them as needed.

- Safety Precautions: Always wear safety glasses when drilling to protect your eyes from flying debris. Secure the workpiece firmly in a vise or clamp to prevent it from moving during drilling. Keep your hands clear of the drill bit and avoid wearing loose clothing or jewelry that could get caught in the drill.

Troubleshooting Common Issues

Even with careful planning and execution, problems can sometimes arise when using the #21 drill size. Here are some common issues and how to address them:

- Drill Bit Breakage: Drill bits can break if they are subjected to excessive force or heat. To prevent breakage, use the correct drill speed, apply lubricant, and avoid forcing the drill bit. If a drill bit breaks, carefully remove the broken piece from the workpiece using pliers or a screw extractor.

- Drill Bit Binding: Drill bits can bind in the hole if the material is too soft or if the hole is not properly lubricated. To prevent binding, use a lubricant and periodically back the drill bit out of the hole to clear chips.

- Inaccurate Hole Size: If the hole size is not accurate, check the drill bit size to ensure that it is the correct size. Also, make sure that the drill bit is sharp and that the drill is running at the correct speed.

- Wandering Drill Bit: A drill bit can wander if it is not properly aligned or if the material is too hard. To prevent wandering, use a center punch to create a starting point for the drill bit. Also, use a slow speed and apply consistent pressure.

Alternatives to the #21 Drill Size

In some cases, the #21 drill size may not be the ideal choice for a particular application. Here are some alternatives to consider:

- Fractional Drill Bits: Fractional drill bits are designated by fractions of an inch. A fractional drill bit that is close in size to the #21 drill size can be used as an alternative.

- Metric Drill Bits: Metric drill bits are designated by millimeters. A metric drill bit that is close in size to the #21 drill size can be used as an alternative.

- Letter Drill Bits: Letter drill bits are designated by letters of the alphabet. These can also be used, although they are less commonly used than numbered, fractional, or metric drill bits.

- Adjustable Drill Bits: Adjustable drill bits allow you to create holes of varying sizes. These can be useful if you need to drill holes of different sizes and don’t want to purchase a separate drill bit for each size.

Conclusion

The #21 drill size is a versatile tool that can be used in a variety of applications. By understanding its dimensions, common uses, and essential considerations, you can ensure accurate and safe drilling. Whether you’re tapping threads, working with sheet metal, or assembling electronics, the #21 drill size can be a valuable addition to your toolkit. Remember to choose the right drill bit material, use the correct drill speed, and apply lubricant to achieve optimal results. Always prioritize safety and take the necessary precautions to protect yourself from injury. [See also: Drill Bit Size Chart] [See also: How to Sharpen Drill Bits] With the right knowledge and techniques, you can confidently tackle any drilling project with the #21 drill size.

Knowing when and how to properly employ the #21 drill size can significantly improve the efficiency and quality of your projects. From ensuring accurate thread tapping to creating precise holes in various materials, this drill size offers a specific solution that is often overlooked. [See also: Understanding Drill Bit Materials] By mastering the use of the #21 drill size, you can elevate your craftsmanship and achieve professional results every time.